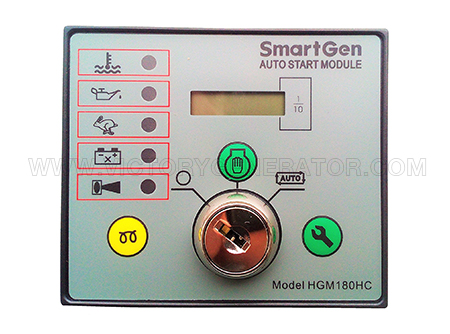

SMARTGEN(ZHENGZHOU) TECHNOLOGY CO., LTD. was established in 1998, a company which was listed on NEEQ. It specializes in design, development, manufacture, sale and service of engine/genset control, ATS and ATS control, engine heaters, battery chargers and related products. Its products are widely used in systems of National Defense, Telecom, Utility Power, Buildings, Marine, Fire Control, etc.

As a high-tech enterprise with a more than 40-person R&D team, SmartGen has successively developed hundreds of control modules with independent intellectual property rights and obtained almost 200 patents. The product technical and quality level leaps into the front ranks of the world.

SmartGen owns standard EMC and environmental labs, dust-free workshop, etc. Its annual sales of product has approached 200,000 and the market share ranks first in China for almost ten years.

SmartGen has passed the ISO9001, ISO14001, GB/T28001, CCSR9001 and GB/T29490 management system certifications. SmartGen is the “AAAA-Class” Enterprise with Good Practice on Standardization and also drafted national standards for genset control module.

SmartGen, which owns nearly 50 offices or agencies in the domestic and overseas, is committed to providing satisfied products and services for customers around the world to achieve win-win cooperation.